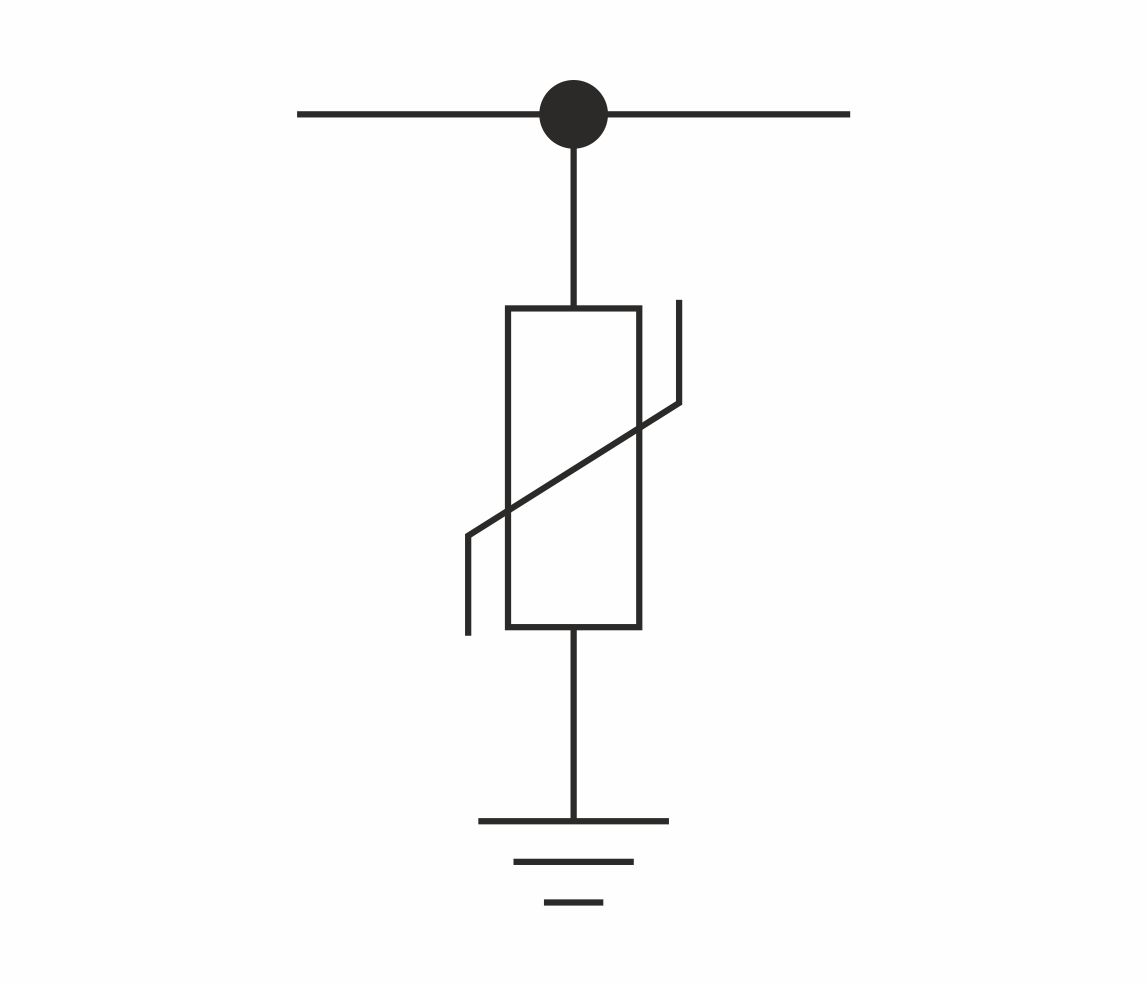

Surge arrester PSP */10/III

PSP */10/III

line discharge class 3

outdoor and indoor use

PSP */10/III - overvoltage limiters designed to protect converter stations and DC systems of electric traction systems linked to them from the effects of atmospheric and switching overvoltage. They are used for protecting traction lines, electrical equipment of trolleybuses, trams and electric trains. They do not require any maintenance during their operation. The PSP */10/III series is intended for outdoor and indoor applications. The functional part of the limiters consists of a column of varistors sized for continuous operating voltage Uc. The outer insulating shell is composed from silicon material (grey colour). The material of the shell shows high resistance to the effects of surface leakage currents and to electric arc, possesses hydrophobic properties and shows excellent resistance to weather effects, pollution and UV radiation. The cover caps, connecting screws, nuts and terminals are made of stainless steel. With their design and technical parameters, the overvoltage limiters of the PSP series conform to the standards EN 60099-4: 2014, IEC 60099-4: 2014 and EN 50526-1: 2012.

| Type | PSP 1/10/III | PSP 2/10/III | PSP 3/10/III | PSP 4/10/III | |

|---|---|---|---|---|---|

| Continuous operating voltage (DC) UC(= Ur) * | 1,25 kV | 2,5 kV | 3,75 kV | 4,2 kV | |

| Nominal discharge current | In | 10 kA | 10 kA | 10 kA | 10 kA |

| Use in power net | 600/750 V | 1500 V | special application |

3000 V | |

| High impulse current (4/10) | 2 x 100 kA | 2 x 100 kA | 2 x 100 kA | 2 x 100 kA | |

| Long current impulse (2 ms) | 850 A | 850 A | 850 A | 850 A | |

| Discharge class acc. to EN 60099-4 | 3 | 3 | 3 | 3 | |

| Residual voltage at In | Ures | ≤ 3,5 kV | ≤ 7 kV | ≤ 10,5 kV | ≤ 10,7 kV |

| Height | h | 83 mm | 90 mm | 102 mm | 110 mm |

| Operating temperature range | - 40 °C ÷ + 55 °C | ||||

| Protection type | IP65 | ||||

| Weight | m | 1,7 kg | 1,9 kg | 2,3 kg | 2,5 kg |

| Article number | 92001 | 92003 | 92004 | 92002 | |

*The rated voltage Ur of the arrester coincides with the continuous operating voltage Uc.

Note: The height and weight are indicative only and may vary. We can send accurate data on your request.

Application possibilities

Electronic systems are more and more sensitive to increasing electromagnetic smog, which can cause interference, system failure or even destruction of the system. It is therefore necessary to use overvoltage protection devices. Direct current traction grids never used to be used as distribution systems but recently there has been an increase in their use for powering various devices in the vicinity of trolleybus and tram tracks, such as switch points, ticket vending machines, cameras, lighting for tram stops, public address systems, security equipment, and the heating of switch points etc. The powering of these devices has always been a problem in respect of transient and switching phenomena, which can be caused by voltage peaks in distribution lines. With DC traction grids the equipment is also influenced by the use of AC/DC traction, and possibly also by the control of transformers with IGBT transistors.

Atmospheric overvoltage

Direct or indirect lightning strike on traction lines, substation buildings, the HV lines of powering substations. Induction onto traction devices.

Switching overvoltage and overvoltage from man-made sources

• crossing dividers (even under power)

• recuperation (braking under the divider), short, but intensive energy peaks

• recuperation and crossing dividers between substations (the most critical case)

• switching of sections in substations

• occurrence of overvoltage in rectifiers and its effect on substations

Advantages

• Long protective distance

• High absorption capacity

• Stable U-I characteristics even after repeated discharges

• Resistance to ageing

• Design resistant to explosion and bursting

• Resistance to pollution and UV radiation

• Resistance of the shell to rough handling

• Maintenance-free design

• Resistance to shocks and vibrations

• High mechanical resistance

Transport and storage

The overvoltage limiters may not be exposed to strong shocks and impacts during transport. They should be stored in the long term in an indoor store.

Maintenance

No testing of the function or maintenance such as cleaning is necessary during the anticipated life of the limiter.